Why Polymer Modified Tile Adhesives Are Essential for Large-Format Tiles

Large-format tiles have reshaped modern architecture—but they’ve also introduced technical challenges that traditional mortars were never designed to solve. Their surface area is massive, their weight is substantial, and their minimal grout lines leave little room for error. As tile sizes reach 600×1200, 750×1500, 900×1800, and even full-size sintered slabs, the bonding layer becomes the make-or-break element of the entire installation.

This is where polymer modified tile adhesive stands out. Not because it is trendy, but because its material science addresses every structural stress that large tiles naturally create.

Hidden Failure Risks of Large-Format Tile Installation

Large tiles fail differently from small tiles. When things go wrong, they usually go wrong rapidly and visibly.

Common failure modes with oversized tiles include:

-

Hollow spots caused by poor wetting under the tile

-

Shear cracks triggered by building movement

-

Warping stress especially in slim sintered slabs

-

Debonding due to low flexibility in the mortar layer

-

Moisture-driven expansion on exterior walls

-

Tile-over-tile separation where old substrate movement is amplified

-

Thermal shock issues near kitchens, balconies, and sun-facing facades

And even worse—many failures come from invisible micro-gaps beneath the tile. A tile that looks perfect on day one may sound hollow on day thirty, or fall off an exterior wall after one season of temperature cycling.

Traditional cement mortar cannot compensate for these stresses. Even with improved mixing ratios, the chemistry simply isn't designed for modern ceramic, porcelain, or sintered stone materials.

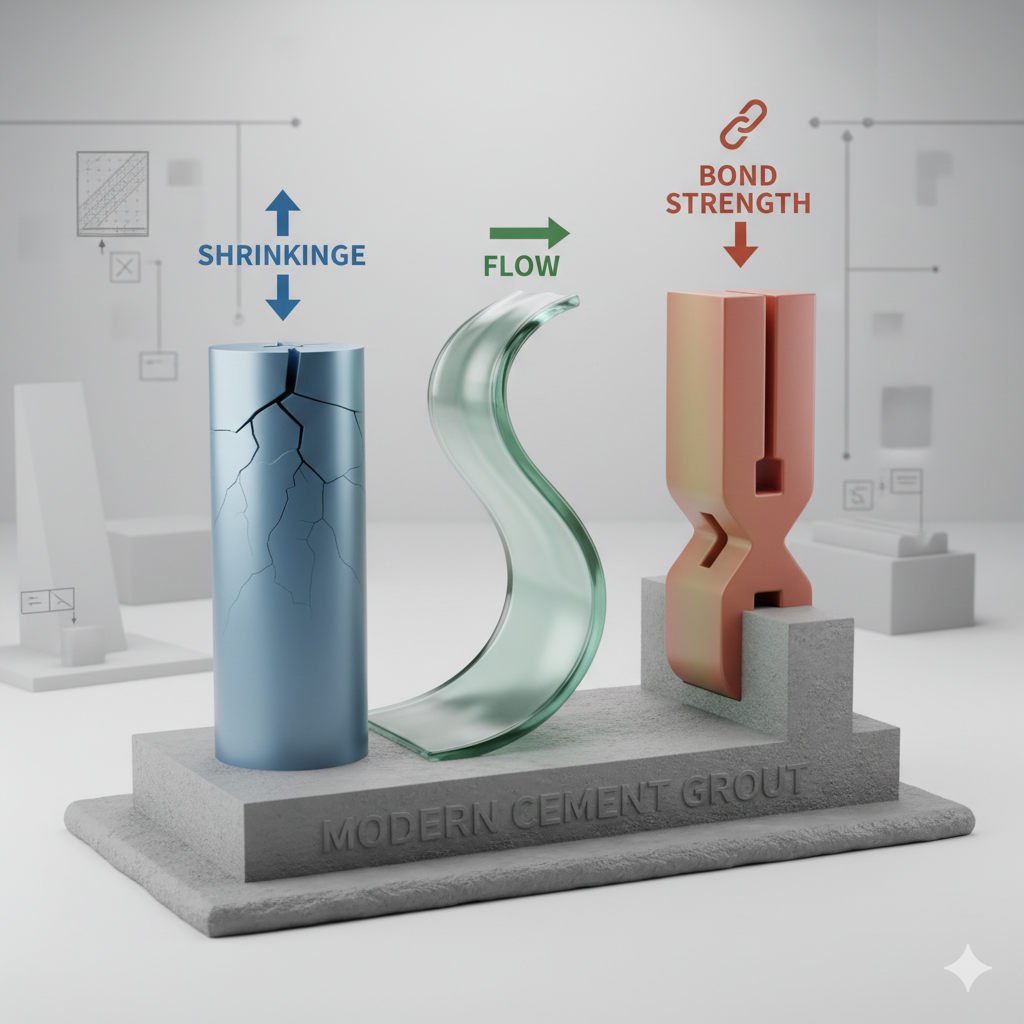

Why Polymer Modification Changes Everything

Polymer modification transforms the adhesive from a simple binder to a performance system. Instead of relying solely on cement hydration, the adhesive introduces:

-

Redispersible polymer powders (RDP) that improve flexibility

-

Higher deformability to absorb tile and substrate movement

-

Improved wetting for full surface contact beneath large tiles

-

Enhanced tensile strength to resist vertical slip

-

Better adhesion to non-porous surfaces such as porcelain or old tiles

In simpler terms:

the adhesive becomes strong where cement is weak, and flexible where cement is brittle.

This is why brands like YUNYAN have shifted their formulations specifically toward large tile applications—modern substrates need modern chemistry.

Technical Comparison: Traditional Mortar vs. Polymer Modified Tile Adhesive

| Performance Factor | Traditional Mortar | Polymer Modified Tile Adhesive |

|---|---|---|

| Bond Strength | Low to Medium | High, consistent |

| Flexibility | Very low | Medium to High (C2/S1/S2) |

| Wetting Coverage | Poor | Excellent |

| Suitable for Large Tiles | ❌ No | ✔ Yes |

| Suitable for Tile-Over-Tile | ❌ No | ✔ Yes |

| Slip Resistance | Low | High, stable |

| Open Time | Short, unpredictable | Long and controlled |

| Water Resistance | Moderate | High |

| Exterior Durability | Weak | Excellent |

Large tiles demand uniform bonding, flexibility, and a chemical backbone that can absorb stress. Only polymer modification provides these properties reliably.

Where Polymer Modified Tile Adhesives Deliver the Biggest Advantages

Below are the environments you指定—all arranged logically to show how the adhesive adapts in different real-world scenarios.

1. Large Floor Tiles (600×1200 / 750×1500 / 900×1800)

What Makes This Scenario Difficult

-

Large tiles amplify subfloor imperfections

-

Heavy weight requires strong initial grab

-

Minimal grout joints mean movement cannot dissipate

How Polymer Modification Helps

-

Flexible layer absorbs floor movement

-

Improved leveling reduces lippage

-

Strong wetting prevents hollow spots

This is especially true for hotels, airports, showrooms, and commercial lobbies where heavy foot traffic demands durability.

2. Sintered Stone Kitchen Countertops & Backsplashes

Challenges

-

Ultra-thin materials (3–6 mm) can warp

-

Heat changes from cooking create expansion cycles

Benefits of Polymer Modified Adhesives

-

Maintains bond strength under thermal stress

-

Reduces crack propagation behind the slab

-

Ensures adhesion on low-porosity surfaces

3. Exterior Walls and Facades

This is where failure becomes dangerous.

Environmental Risks

-

UV exposure

-

Rain + moisture ingress

-

Freeze–thaw cycles

-

Wind pressure and building movement

Why Polymer Modification Is Essential

-

Provides weather-resistant flexibility

-

Prevents moisture-related debonding

-

Maintains bond strength despite thermal expansion

A traditional mortar layer simply cannot manage these stress cycles.

4. Commercial Space Installations

Hotels, malls, gyms, restaurants—these areas combine foot traffic, cleaning chemicals, temperature fluctuation, and vibration.

Polymer modified adhesives:

-

Increase durability under constant load

-

Improve long-term bonding on high-density porcelain tiles

-

Extend maintenance intervals (lower lifetime cost)

This is why many commercial contractors specify S1 or S2 deformability as a baseline.

5. Tile-Over-Tile Renovation

A rapidly growing application.

The Problem

Old tiles are:

-

non-porous

-

unstable

-

prone to micro-movement

The Solution

Polymer modified tile adhesive adheres directly to smooth surfaces, allowing fast renovation without demolition.

This is also a core advantage promoted in YUNYAN’s product lineup, favored by many modernization projects.

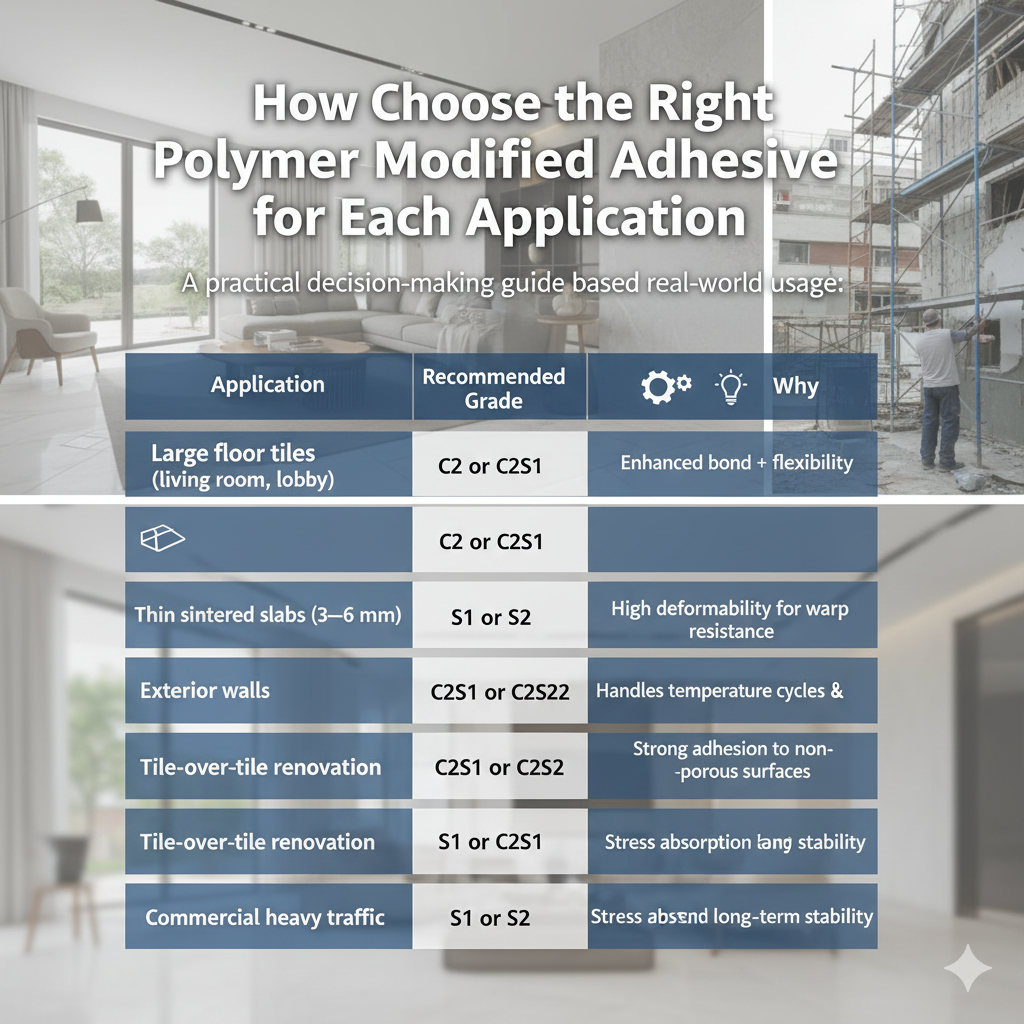

How to Choose the Right Polymer Modified Adhesive for Each Application

A practical decision-making guide based on real-world usage:

| Application | Recommended Grade | Why |

|---|---|---|

| Large floor tiles (living room, lobby) | C2 or C2S1 | Enhanced bond + flexibility |

| Thin sintered slabs (3–6 mm) | S1 or S2 | High deformability for warp resistance |

| Exterior walls | C2S1 or C2S2 | Handles temperature cycles & moisture |

| Tile-over-tile renovation | C2 or C2S1 | Strong adhesion to non-porous surfaces |

| Commercial heavy traffic | S1 or S2 | Stress absorption and long-term stability |

If a project carries structural movement, temperature swing, or has low-porosity materials, an S1 or S2 adhesive is no longer optional—it is necessary.

Short Optimized Closing Paragraph

Large-format tiles look seamless only when the bonding layer performs as expected. Polymer-modified adhesives provide that stability across heat, movement, and daily load. For teams evaluating materials or planning upcoming installations, you can explore more technical references on YUNYAN’s homepage or request project-specific guidance through the contact page .