What Makes Ceramic Tile Adhesives Work So Well in Modern Homes and Buildings

Modern homes and commercial buildings demand finishes that are stronger, cleaner, and more enduring than ever before. Tiles are an essential part of this shift—appearing in bathrooms, kitchens, balconies, facades, and high-traffic public spaces. But despite advances in tile technology, many construction failures still come down to one often overlooked element: the adhesive beneath the tile.

Why do some tiles stay firmly bonded for decades while others crack, lift, or detach within months? The answer lies in how today’s ceramic tile adhesives are engineered—and why they’ve become the preferred choice for builders and installers everywhere.

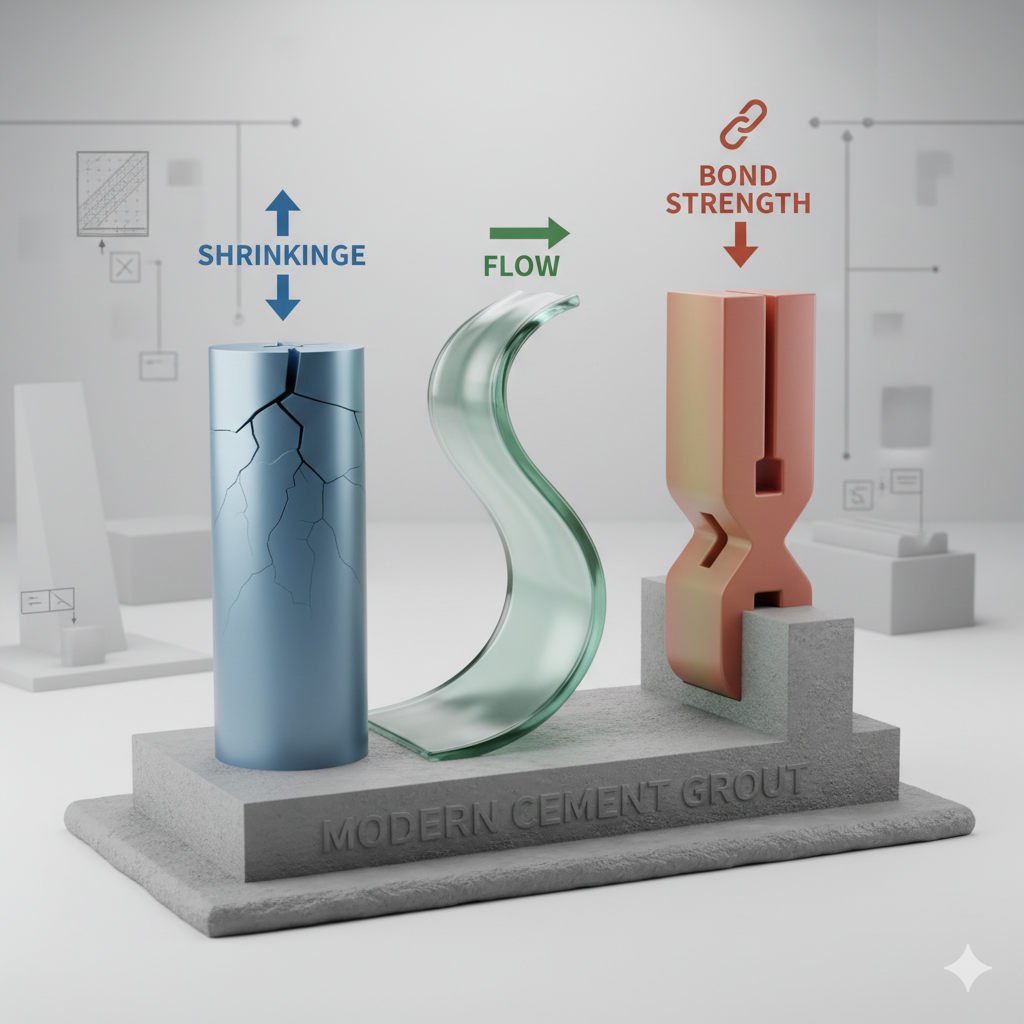

Why Traditional Mortar Struggles in Modern Construction

Many installers are familiar with cement-sand mortar. It’s cheap, it’s familiar, and it seems reliable—until tiles begin to loosen or sound hollow. Modern buildings introduce challenges that mortar was never designed to handle:

Common Problems With Mortar in Today’s Environments

-

Poor adhesion on low-absorption tiles (porcelain, glazed ceramic)

-

Slippage on vertical walls, creating misalignment and rework

-

Inconsistent bond strength due to manual mixing

-

Weak water resistance, causing bathrooms and kitchens to deteriorate quickly

-

High shrinkage, leading to cracks and hollow spots

But the bigger risk today comes from low-quality adhesives sold as budget alternatives. Many look similar on the surface, but inside the bag, the formulation often compromises performance:

Typical Issues With Low-Grade Tile Adhesives

-

Excess fillers instead of true polymer content

-

Batch inconsistency that changes workability every few bags

-

Grainy, hard-to-spread texture that fatigues installers

-

Inability to withstand moisture, temperature shifts, or external stress

-

Almost no slip resistance—especially dangerous on large-format wall tiles

These problems translate into callbacks, customer complaints, and expensive rework. In modern buildings, where tile types and substrates vary widely, such risks are amplified.

Why Modern Ceramic Tile Adhesives Perform So Well

The evolution from mortar to engineered adhesives is rooted in polymer science. Today’s adhesives—especially formulations from established manufacturers like YUNYAN—combine cement, selected fillers, and advanced polymers to create a bonding material that adapts to real installation challenges.

What Makes Engineered Adhesives Superior?

-

Polymer Flexibility

Prevents cracks by absorbing small structural movements—critical in exterior walls, balconies, and high-rise buildings. -

High Initial Grab

Tiles stay firmly in place during installation, reducing slippage and achieving better alignment. -

Improved Water Retention

Ensures even curing and minimizes tile detachment in humid spaces like bathrooms and kitchens. -

Controlled Viscosity

Spreads smoothly and consistently, reducing installer fatigue and improving tile coverage. -

Predictable Performance

Unlike mortar, every bag performs the same—essential for professional projects handled by ceramic tile adhesive suppliers and contractors.

This combination of stability, strength, and ease of use explains why these adhesives dominate today’s construction market.

Performance Comparison: Mortar vs. Low-Grade Adhesive vs. Modern Formulation

| Performance Factor | Traditional Mortar | Low-Grade Adhesive | High-Quality Adhesive (e.g., YUNYAN Standard) |

|---|---|---|---|

| Bond Strength | Low–medium | Unstable | High, consistent |

| Slip Resistance | Weak | Poor | Excellent |

| Water Resistance | Low | Very low | Outstanding |

| Workability | Hard to spread | Grainy | Smooth, installer-friendly |

| Drying Time | Long | Variable | Controlled, efficient |

| Coverage Efficiency | Low | Medium | High |

| Long-Term Durability | Unpredictable | Weak | Proven in multi-environment performance |

Where mortar fails and low-quality adhesives struggle, engineered adhesives maintain stability across climate zones, substrates, and tile types.

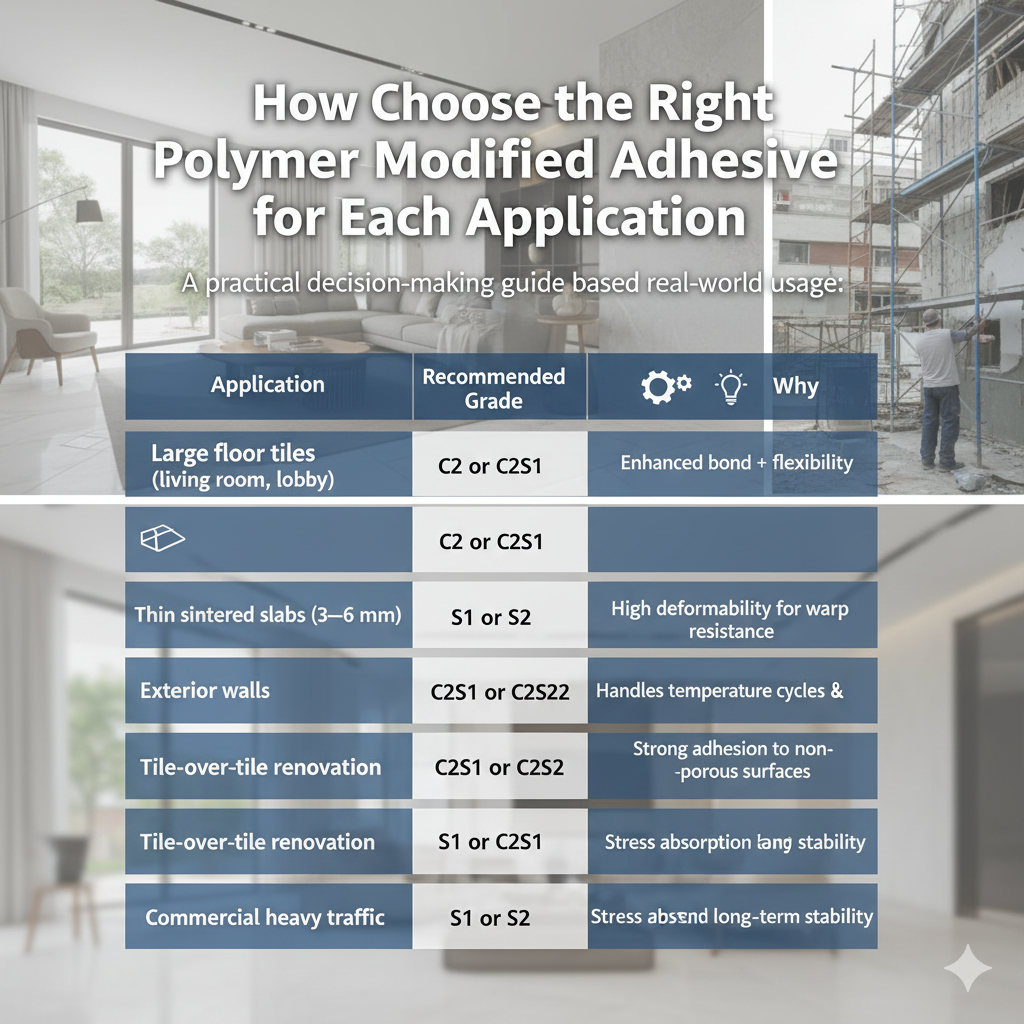

Where Ceramic Tile Adhesives Excel: Real Usage Scenarios

A major reason ceramic tile adhesives work so well is their versatility. Instead of one formula for everything, different blends support different environments—something impossible with traditional mortar.

Environment-Based Selection Guide

| Installation Area | Recommended Adhesive Type | Key Strengths | Notes |

|---|---|---|---|

| Bathrooms | Waterproof Adhesive | Moisture resistance, anti-mold | Suitable for floors and wet walls |

| Kitchens | High Bond Strength Adhesive | Heat & stain resistance | Ideal for splash zones |

| Exterior Walls | Flexible Polymer Adhesive | UV, heat & thermal movement resistance | Critical for high-rise façades |

| Balconies | Elastic Adhesive | Anti-crack, weather resilience | Handles expansion and contraction |

| Renovation (tile-over-tile) | Fast-Setting Adhesive | Strong initial grab | Saves installation time |

Installers appreciate adhesives not just for bonding ability, but for how much easier and cleaner they make the job. Even in challenging settings, modern adhesives maintain control, consistency, and long-term reliability.

How These Adhesives Perform in Real Projects

Professional installation teams and distributors often highlight improvements after switching to reliable adhesive technology:

Observed Benefits

-

30% faster installation in commercial flooring

-

Fewer hollow tiles in wet areas such as hotel showers

-

Stronger adhesion on exterior walls facing extreme heat

-

Better tile alignment due to controlled slip resistance

-

Ability to support large-format tiles and heavy stone pieces

Many partners working with YUNYAN note measurable drops in callback rates, rework, and customer complaints after upgrading adhesive quality.

The Material Behind the Finish

Tiles may define the visible style of a space, but adhesives define how well that space lasts. The rising preference for ceramic tile adhesives isn’t a trend—it’s a reflection of real project requirements: durability, consistency, and adaptability to modern building environments.

For builders, installers, and distributors seeking long-term reliability, partnering with a trusted supplier makes all the difference. To learn more about engineered bonding materials and practical application solutions, visit the homepage or connect through the contact page for project-specific support.