Epoxy Grout Explained: Strength, Chemical Resistance, and Seamless Finishing

In today’s construction industry, appearance and durability are no longer separate goals—they must coexist. The grout between tiles is often the first element to show age, discoloration, or water damage. While cement-based products still dominate residential markets, epoxy grout has become the go-to solution for environments that demand both aesthetic longevity and technical endurance.

Why Traditional Grout Fails in Demanding Environments

Even well-formulated cement grout has inherent limitations. Its micro-porous structure absorbs moisture, stains, and cleaning chemicals. In high-use or high-humidity environments such as commercial kitchens, swimming pools, hospitals, or retail centers, this absorption leads to:

-

Color fading and staining from oils or detergents

-

Cracking and shrinkage under repeated cleaning or thermal shock

-

Mold and bacteria growth in damp joints

-

Erosion of surface texture after frequent scrubbing

These issues accumulate over months, not years—making replacement costly and disruptive. The rise of epoxy grout is a direct response to these recurring failures.

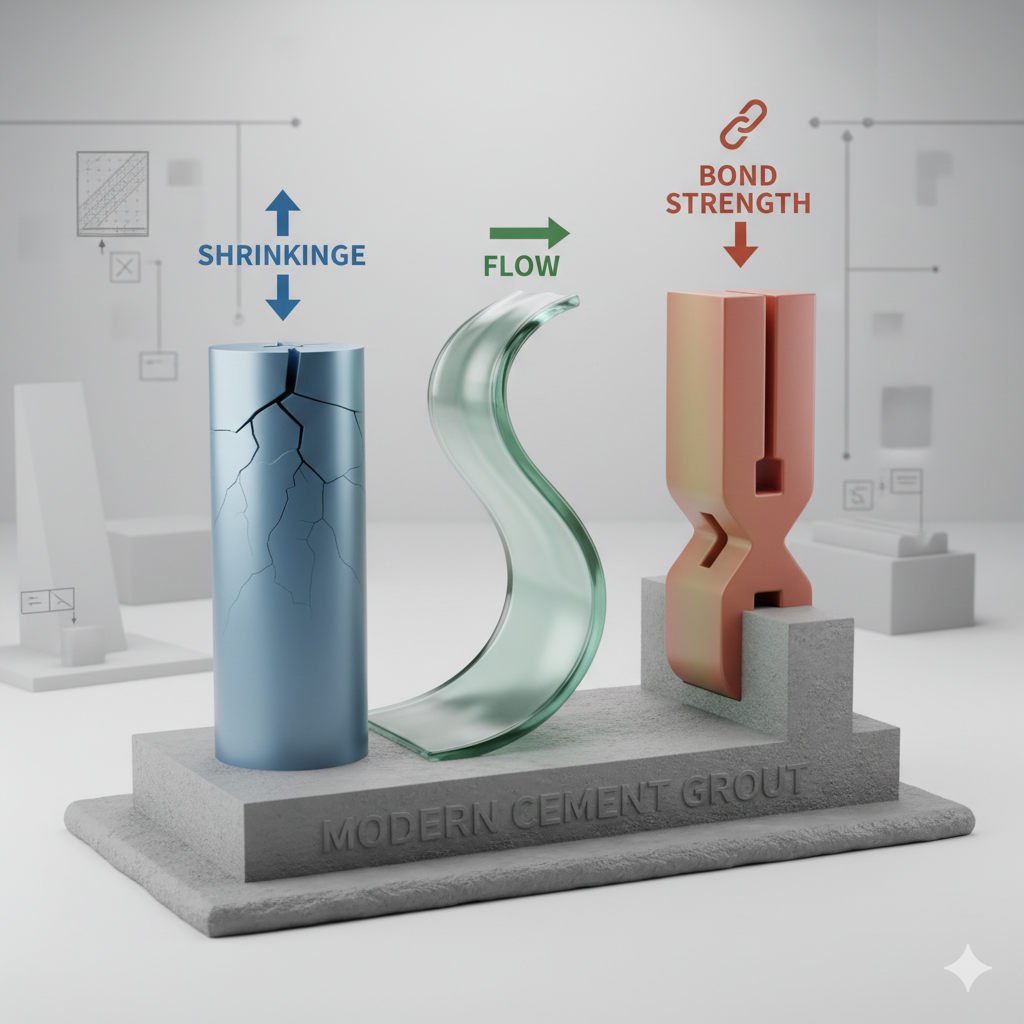

What Makes Epoxy Grout Structurally Different

Epoxy grout replaces cement hydration chemistry with a resin-hardener reaction, forming a dense, impermeable matrix. It contains no water, meaning no shrinkage during curing, and forms a bond that’s both chemical and mechanical.

Key Material Properties

| Property | Epoxy Grout | Cement Grout |

|---|---|---|

| Water Absorption | < 0.1% | 3–6% |

| Shrinkage | Negligible | Moderate to high |

| Flexural Strength | 15–20 MPa | 3–5 MPa |

| Stain Resistance | Excellent | Poor |

| Chemical Resistance | High | Low |

| Color Stability | Long-term | Prone to fading |

| Maintenance | Easy wipe-clean | Requires periodic sealing |

Epoxy’s non-porous surface resists chemical attack and does not absorb dirt or moisture, making it ideal for hygiene-critical or industrial settings.

Unlike cement grout, its curing reaction continues even in humid conditions, ensuring consistent results in both indoor and outdoor applications.

The Real-World Advantages Behind the Gloss

The glossy finish of epoxy grout isn’t just about aesthetics—it’s an outcome of molecular density. Each cured joint becomes a sealed barrier that prevents liquids, grease, and pathogens from penetrating.

Practical Benefits

-

Durability: Maintains joint integrity under vibration and load

-

Hygiene: Non-porous, antibacterial, and easy to sanitize

-

Low Maintenance: No resealing required over years of use

-

Chemical Resistance: Withstands acids, bleach, and cleaning agents

-

Color Retention: UV-stable pigments keep surfaces looking uniform

Because of these traits, epoxy grout has become the default choice in commercial kitchens, medical facilities, food processing plants, and swimming pools—anywhere hygiene and performance are non-negotiable.

Challenges and Misconceptions About Epoxy Grout

Despite its superior performance, epoxy grout still carries misconceptions in the market:

-

“It’s too difficult to apply.”

Modern systems are pre-weighed, easy to mix, and designed with longer working times. Installers just need proper tools and timing. -

“It’s only for industrial use.”

New low-viscosity formulations from brands like YUNYAN make epoxy grout ideal for homes, spas, and decorative interiors. -

“It’s too expensive.”

While upfront cost is higher, epoxy grout reduces lifetime maintenance, cleaning effort, and replacement frequency—often lowering total project cost.

By addressing these myths, many construction teams now view epoxy systems as practical rather than luxury options.

Application Scenarios: Where Epoxy Grout Excels

| Environment | Performance Requirement | Why Epoxy Grout Wins |

|---|---|---|

| Commercial Kitchens & Restaurants | Stain and heat resistance | Prevents oil absorption, easy cleanup |

| Hospitals & Laboratories | Sterile, non-porous joints | Inhibits bacterial growth |

| Swimming Pools & Spas | Water immersion resistance | Zero absorption, color stable |

| Retail & Public Facilities | Heavy foot traffic | High wear resistance |

| Luxury Interiors | Seamless appearance | Uniform color, glossy finish |

Whether in kitchens or clinics, epoxy grout ensures not only aesthetics but also safety and compliance with hygiene standards.

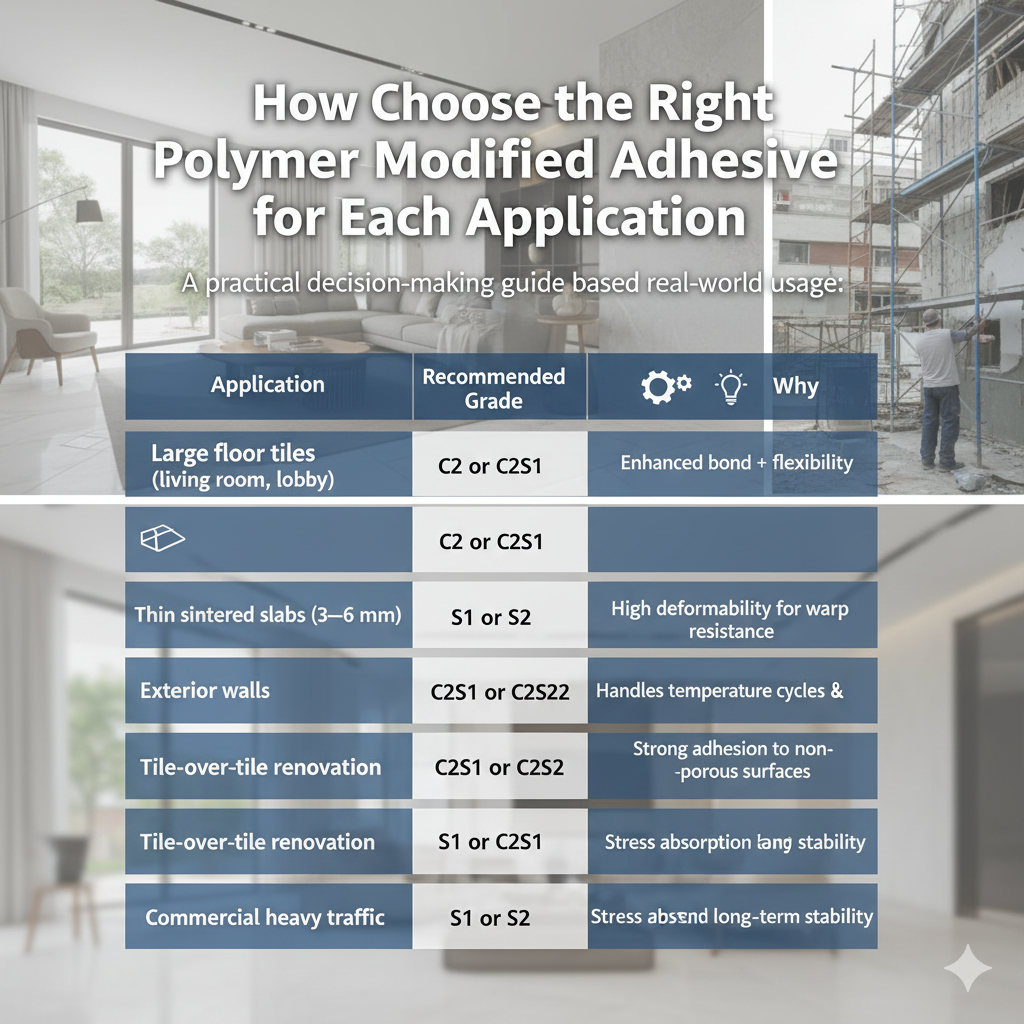

How to Choose the Right Epoxy Grout System

When selecting an epoxy grout, professionals should focus on performance categories rather than brand names.

Selection Checklist:

-

Verify compressive strength (>50 MPa) for load-bearing floors

-

Choose UV-resistant pigments for outdoor or sunlit areas

-

Use low-viscosity types for narrow joints (<2 mm)

-

Opt for high thixotropy products for vertical applications

-

Check for low VOC emissions to comply with green building standards

Leading exporters such as YUNYAN design epoxy grout systems that balance workability and long-term durability, simplifying installation without compromising performance.

Integrating Epoxy Grout Into Modern Design Systems

Architects increasingly specify epoxy grout not as an accessory but as part of the tile system design.

The uniform color finish enhances large-format aesthetics, while its chemical stability reduces maintenance cycles.

It bridges the gap between industrial-grade performance and architectural appearance, which explains its adoption in hotels, airports, and high-end residential projects.

Built for Environments That Never Stop Moving

Epoxy grout embodies what modern construction requires—durability under stress, consistency under exposure, and visual harmony that endures. While it demands precision during installation, its long-term reward is structural confidence and hygiene sustainability.

For detailed technical data and formulation insights, visit YUNYAN’s homepage.

If your project involves food processing, hospitality, or other demanding environments, our specialists can provide tailored material recommendations through the contact page.

A grout that never absorbs, never fades, and never cracks isn’t just a product—it’s a system built for permanence.