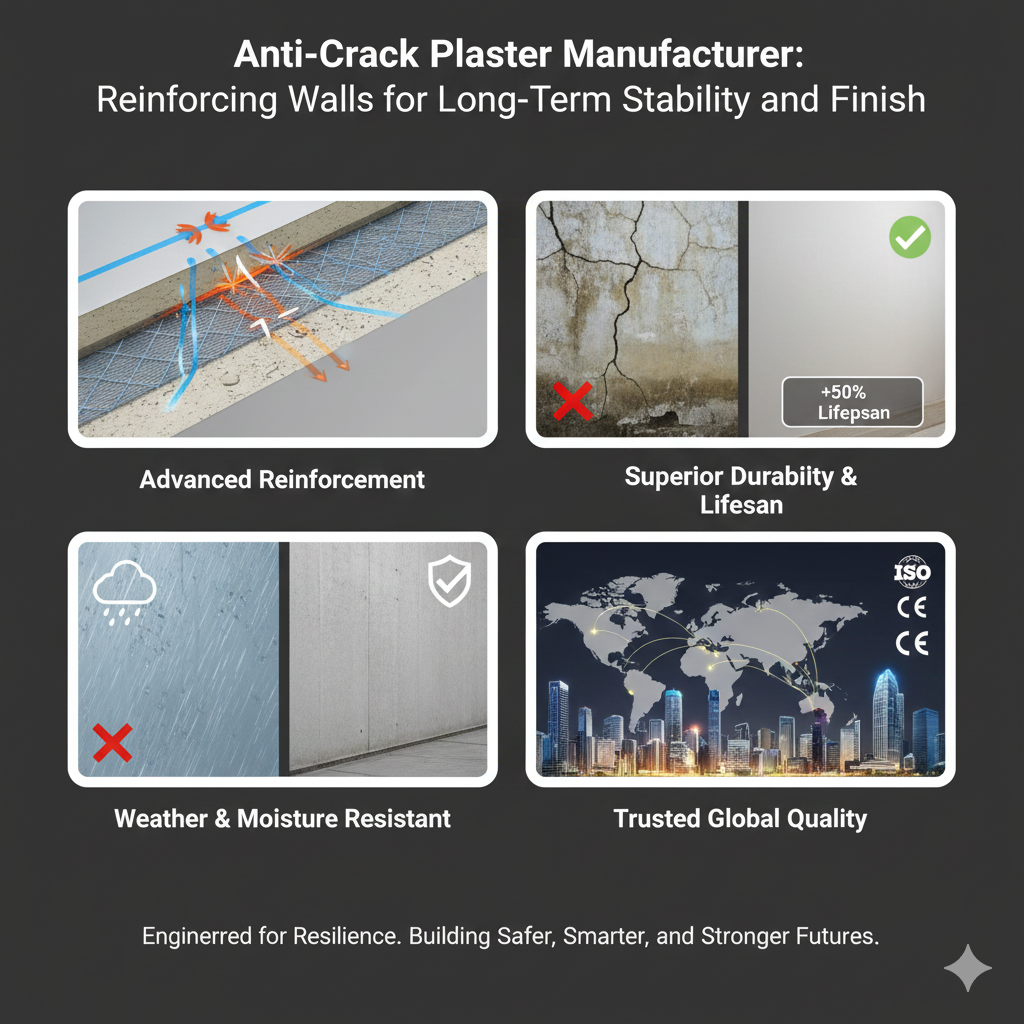

Anti-Crack Plaster Manufacturer: Reinforcing Walls for Long-Term Stability and Finish

Every crack tells a story—of stress, temperature change, or time.

For builders, homeowners, and contractors alike, cracked walls are not just visual defects; they indicate failure in bonding, flexibility, or curing.

That’s why anti-crack plaster has become a foundational material in modern construction, engineered to move with the wall rather than break against it.

1 | When Walls Start to Crack — The Real Pain Behind the Surface

Cracks are caused by multiple interacting factors:

-

Thermal expansion and contraction from sunlight and temperature cycles.

-

Moisture migration between substrate and finish layer.

-

Structural vibration or load changes in high-rise or industrial buildings.

-

Shrinkage during curing, especially in conventional cement-based plasters.

These micro-cracks gradually lead to:

-

Water ingress and mold growth.

-

Paint peeling or detachment.

-

Reduced structural adhesion.

-

Costly surface rework within months of handover.

Traditional plasters—rigid and brittle—cannot adapt to structural movement, making flexible anti-crack systems the smarter alternative.

2 | What Makes an Anti-Crack Plaster Work

YUNYAN’s anti-crack plaster combines cementitious strength with polymer flexibility, enhanced by micro-fiber reinforcement.

This tri-system approach ensures the plaster can stretch, contract, and recover without losing adhesion.

| Component | Function | Technical Effect |

|---|---|---|

| Cementitious Base | Structural bonding | Provides core strength and adhesion |

| Polymer Modifier | Elasticity & bonding | Improves flexibility (elongation ≥ 2%) |

| Glass or Cellulose Fibers | Crack resistance | Distributes stress across surface |

| Shrinkage Reducers | Dimensional stability | Prevents micro-fissures during curing |

| Hydrophobic Additives | Moisture barrier | Stops water penetration and efflorescence |

Performance Data (YUNYAN standard test):

-

Adhesion ≥ 0.35 MPa (on concrete)

-

Flexural strength ≥ 5.0 MPa

-

Crack width resistance ≤ 0.05 mm under 10,000 load cycles

3 | Comparison: Regular vs. Anti-Crack Plaster Systems

| Feature | Conventional Cement Plaster | YUNYAN Anti-Crack Plaster |

|---|---|---|

| Flexibility | Low (brittle) | High (polymer modified) |

| Crack Resistance | Poor | Excellent (fiber reinforced) |

| Adhesion Strength | Moderate | > 0.35 MPa |

| Thermal Expansion Control | Weak | Stable across temperature cycles |

| Curing Shrinkage | 0.1–0.15% | ≤ 0.05% |

| Surface Smoothness | Uneven after drying | Uniform, ready for finishing |

In essence, anti-crack plaster acts like a shock absorber, distributing internal stress before it becomes visible damage.

4 | Inside YUNYAN’s Manufacturing Precision

Each batch is produced under a fully automated mixing line with ISO 9001 and EN 998-1 quality standards.

Process Overview:

1️⃣ Raw Material Selection: Polymer sourced from BASF-certified suppliers.

2️⃣ Weighing & Mixing: Formula ratio tolerance within ±0.3%.

3️⃣ Fiber Distribution: 3D dispersal technology ensures even reinforcement.

4️⃣ Moisture-Proof Packaging: Sealed 25kg export bags prevent humidity absorption.

5️⃣ Performance Testing: ASTM C1583 (adhesion) and ASTM C109 (compressive) validation before shipment.

OEM partners benefit from custom branding, color adjustments, and regional climate formulations—from hot humid to dry temperate zones.

5 | Field Application: Smooth Performance Meets Flexibility

| Step | Application | Key Control |

|---|---|---|

| 1. Surface Preparation | Clean, sound substrate | Remove dust, oil, or weak layers |

| 2. Primer Coating | Polymer primer for bonding | Prevents delamination |

| 3. Mixing | 25–27% clean water | Machine mix for 3 mins |

| 4. Application | 2–3 coats, 10–15mm thickness | Apply mesh for critical areas |

| 5. Curing | Moist cure 48h | Avoid direct sunlight |

For renovation projects, anti-crack plaster is ideal for recoating old concrete, repairing wall fissures, and strengthening thermal insulation layers.

6 | Where Anti-Crack Plaster Makes a Difference

| Application Zone | Challenge | Solution |

|---|---|---|

| Exterior Walls | Temperature-induced cracking | Polymer flexible formula |

| Interior Walls | Dry shrinkage and vibration | Fiber-reinforced version |

| Wet Areas (Bathrooms) | Moisture + heat cycles | Hydrophobic modifier system |

| Old Building Renovations | Uneven substrate | High-adhesion patching mortar |

| Industrial Structures | Vibration & thermal stress | High-elasticity reinforced coating |

The adaptability of anti-crack plaster makes it suitable across residential, commercial, and infrastructure projects.

7 | Long-Term Benefits and Sustainability

-

Reduces maintenance frequency by 40–60%.

-

Prevents water ingress and paint failure, extending wall life.

-

VOC-free and low dust emission, safe for indoor use.

-

Compatible with thermal insulation systems, enhancing building performance.

-

Supports LEED and ISO 14001 sustainability goals.

Each layer of YUNYAN’s anti-crack plaster is built not only for strength—but also for the longevity of the entire wall system.

Cracks Stop Here — Build Stronger with YUNYAN

Cracks are inevitable in ordinary walls—but not in engineered systems.

With YUNYAN’s anti-crack plaster, builders achieve seamless finishes, long-term adhesion, and stress-resistant performance that stand the test of time.

For OEM partnership, private label, or export collaboration, visit YUNYAN’s homepage or contact the technical team through contact page to access tailored solutions for your next project.