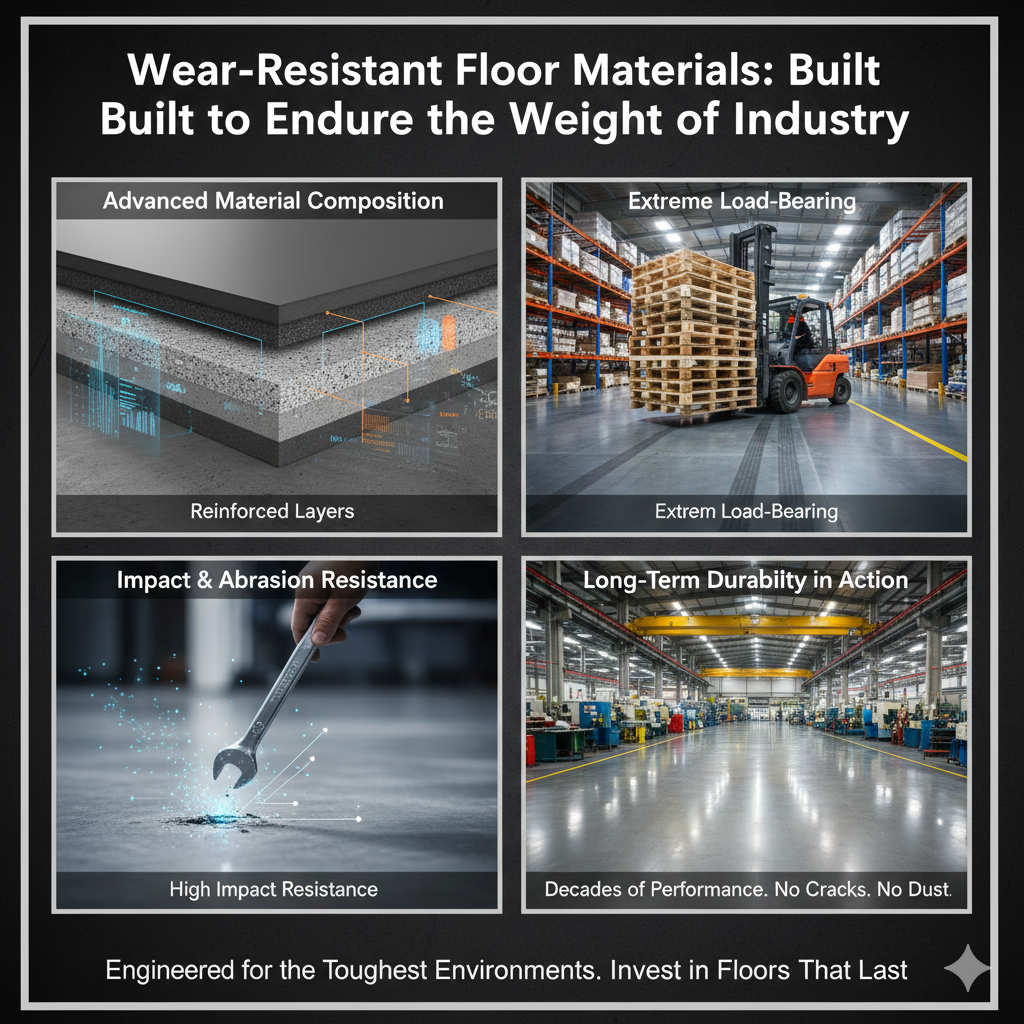

Wear-Resistant Floor Materials: Built to Endure the Weight of Industry

When forklifts run, cranes rotate, and pallets grind against concrete—floors face a daily assault few materials can survive.

Ordinary cement floors may look solid, but their top layer erodes quickly under constant friction. The result?

Dust, dents, and degradation that slow operations and shorten service life.

To meet these demands, modern manufacturers rely on wear-resistant floor materials—engineered systems designed to reinforce and harden the surface, ensuring it stands strong against mechanical stress and time.

1 | The Real Pain: Floors That Wear Faster Than Machinery

Every industrial facility faces the same reality—floors fail long before equipment does.

Common failure patterns include:

-

Surface dusting from friction and micro-abrasion.

-

Impact pitting under dropped loads.

-

Wheel rutting from forklifts and AGVs.

-

Oil and chemical staining weakening the concrete matrix.

-

Micro-cracking that propagates under cyclic loads.

Once degradation starts, it accelerates—creating maintenance downtime and safety risks.

A wear-resistant floor isn’t luxury; it’s essential infrastructure.

2 | Engineering the Material: From Mineral Science to Molecular Bonding

The strength of a floor comes from what’s inside its top 5 millimeters.

YUNYAN’s wear-resistant materials combine graded quartz or corundum aggregates, high-strength binders, and polymer modifiers to create dense, abrasion-proof surfaces.

| Component | Function | Technical Contribution |

|---|---|---|

| Quartz / Corundum Aggregate | Mechanical hardness | Increases surface wear resistance (Mohs ≥ 8) |

| Cementitious Matrix | Base binding structure | Provides compressive strength > 90 MPa |

| Polymer Additives | Flexibility and bonding | Prevents delamination and cracking |

| Silicate Densifier | Chemical sealing | Fills pores and prevents dusting |

| Pigment & Stabilizers | Aesthetic durability | Retains color under UV & chemical exposure |

The result is a monolithic surface that doesn’t flake or peel—even under forklift tires or high-frequency traffic.

3 | Comparing System Types: Selecting the Right Strength Class

| System Type | Base Material | Key Advantage | Ideal Use |

|---|---|---|---|

| Dry-Shake Hardener | Quartz / corundum + cement | Integrates with fresh concrete | New warehouse or plant floors |

| Epoxy-Modified Coating | Epoxy resin + mineral filler | Chemical & abrasion resistance | Chemical and automotive plants |

| Polyurethane Hybrid Layer | PU + fine aggregate | High impact flexibility | Cold storage, logistics centers |

| Silicate Densified Floor | Lithium silicate | Deep penetration hardening | Existing floors under renovation |

Each system delivers a balance between mechanical toughness and application practicality.

Export-oriented projects often prefer dry-shake or silicate-based hardeners for long lifespan and minimal maintenance.

4 | Inside YUNYAN’s Manufacturing and Quality Process

YUNYAN’s production facilities follow strict ISO and ASTM protocols to ensure consistency across export batches:

1️⃣ Raw Material Grading – Aggregates sieved and classified (0.5–2.5 mm range).

2️⃣ Binder Optimization – Compressive strength tested using ASTM C109.

3️⃣ Thermal Expansion Control – Mixes tested for dimensional stability (≤ 0.02%).

4️⃣ Abrasion Testing – Evaluated per ASTM C944 with loss < 0.05 g.

5️⃣ Color and Finish Verification – UV chamber test for 1000h exposure.

Each batch undergoes QC certification before shipment—guaranteeing uniform color, hardness, and moisture stability even in tropical climates.

5 | Installation Process: From Base to Bulletproof Surface

| Step | Description | Technical Note |

|---|---|---|

| 1. Base Preparation | Leveling and cleaning of fresh or old concrete | Remove laitance and dust |

| 2. Application (Dry-Shake or Trowel) | Even distribution over wet concrete | Apply 3–5 kg/m² depending on traffic |

| 3. Power Troweling | Mechanical compaction to densify surface | Perform 2–3 passes for high gloss |

| 4. Curing and Densifying | Use silicate sealer for chemical hardening | Curing time: 7 days |

| 5. Final Polish (Optional) | Improves sheen and smoothness | Surface roughness ≤ 0.8 μm |

Proper troweling is critical: each pass aligns aggregate particles closer to the surface, producing a dense, metallic-like sheen that defines premium-grade wear-resistant floors.

6 | Application Scenarios: Built for Real-World Pressure

| Industry | Challenge | Recommended System | Performance Outcome |

|---|---|---|---|

| Automotive Factory | Tire abrasion, oil exposure | Epoxy-mineral hybrid | Chemical and mechanical protection |

| Logistics Warehouse | Forklift wear | Dry-shake corundum system | 10x abrasion resistance vs. plain concrete |

| Cold Storage Facility | Thermal shock | PU hybrid coating | Maintains adhesion under -20°C cycles |

| Airport Hangar | Heavy wheel loads | Quartz cementitious system | Surface strength > 100 MPa |

| Commercial Mall | Foot traffic + aesthetics | Pigmented hardener | Glossy, durable finish |

Across industries, YUNYAN’s wear-resistant flooring solutions combine strength, endurance, and visual consistency, ensuring long-term ROI.

7 | Common Mistakes to Avoid

-

Applying hardener on too dry or over-cured concrete → poor bonding.

-

Inadequate compaction or curing → dusting returns within months.

-

Ignoring joint sealing → cracks transfer through hardened layer.

-

Using ungraded aggregates → uneven hardness across surface.

Proper application isn’t just material science—it’s process discipline.

YUNYAN provides detailed TDS (Technical Data Sheet) and training for OEM partners and contractors worldwide.

8 | Sustainable Strength: The New Standard

Modern wear-resistant flooring goes beyond endurance.

-

Low VOC and dust-free application ensure worker safety.

-

Extended lifecycle reduces carbon footprint from repairs.

-

Recyclable packaging and optimized logistics cut CO₂ per ton shipped.

YUNYAN’s R&D team continually refines formulations for greener, longer-lasting floors—built to meet the sustainability goals of next-generation infrastructure.

Strength That Doesn’t Fade

A factory’s productivity depends on the ground it stands on.

When wear, heat, and time strike daily, your floor’s resilience defines your reliability.

YUNYAN’s wear-resistant floor materials provide that strength—crafted with precision, tested under pressure, and proven across industries.

For export specifications, OEM partnerships, or technical consultations, visit the YUNYAN official website.

To request data sheets or product customization, reach our engineers through contact page and build a foundation that outlasts the machinery it supports.